About Us

Your ideas. Your brand. Taylor brings them to life.

We engineer print solutions that build businesses. Taylor’s combination of printed products, digital services and integrated technology is the largest in the communications industry.

Industry-Leading Technologies

Unmatched Print Capabilities

Worldwide Reach

We engineer print solutions that build businesses. Taylor’s combination of printed products, digital services and integrated technology is the largest in the communications industry.

Industry-Leading Technologies

Unmatched Print Capabilities

Worldwide Reach

Powering brands by empowering people

We are committed to our communities, culture and the environment. We care about the world around us and demonstrate it by investing and participating in initiatives that connect people, enrich lives, and support health and sustainability.

Community Outreach and Involvement

Our business and teams of employees help improve the communities in which we live and work. We contribute through leadership involvement, volunteerism and sponsored events.

Diversity, Equity and Inclusion

Shaping the company’s culture is an inseparable part of our business strategy. Taylor will not waver from its resolve to make a difference for all minority populations in a way that respects and empowers every individual to express their voice and their authentic self.

Being the Change We Want to See

We see diversity and inclusion as fundamental business philosophies. The logic is simple: diversity and inclusion programs make our businesses better. They help us recruit new employee talent. They connect on a deeper level with our customers.

Minority-and Women-Owned Businesses (MWBE)

Taylor is dedicated to creating economic strength — in our communities and across the country — through our efforts to support and assist minority-and women-owned companies. These relationships ultimately strenghten both to Taylor and supplier organiations themselves.

Sustainability, Health and Safety

We are committed to applying our global knowledge and expertise to continually improve safety, wellness, environmental performance and sustainability.

A global print provider trusted by the top brands.

We’re one of the top 10 graphic communications companies in all of North America. We’re behind the marketing of businesses you interact with every day.

The industry’s broadest array of printed products and digital services.

“The width and breadth of the solutions that Taylor brings to the table. The service. The support. The high level of execution. It’s invaluable to get all of that in one partner.”

Craig Moen

Sr. Retail Experience Design Manager at Red Wing Shoe Co.

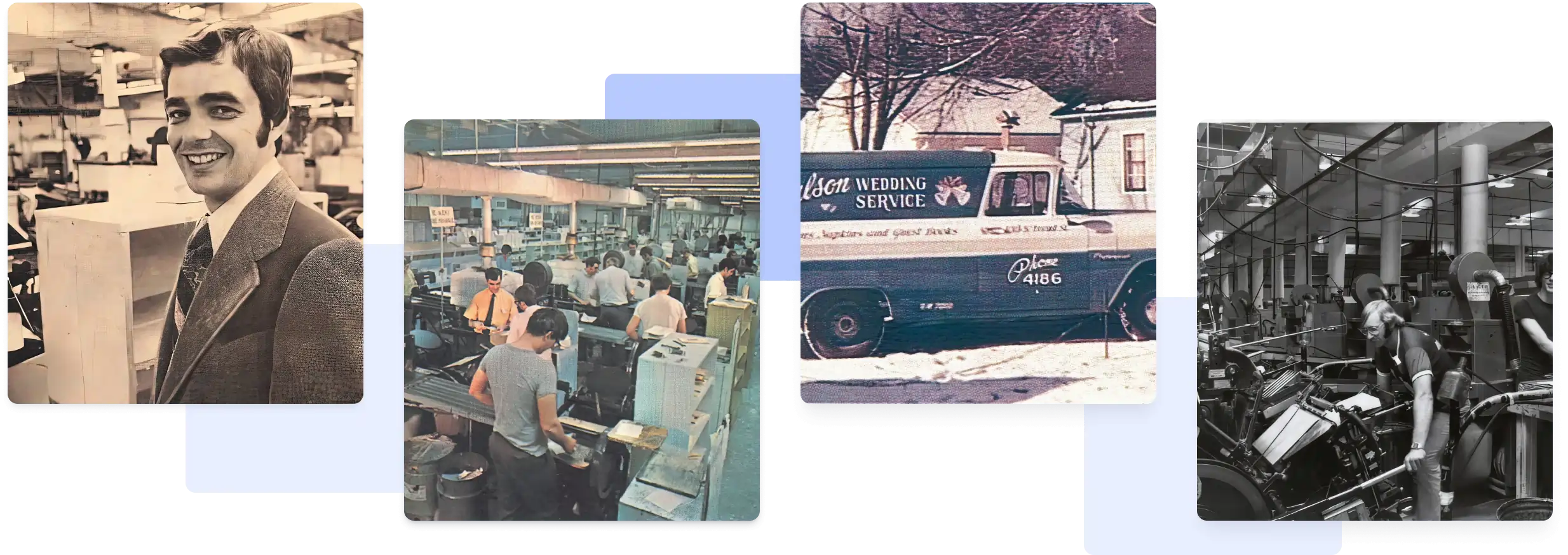

Taylor’s History

An American Success Story

In 1959, Glen Taylor took a job at Carlson Wedding Services, a small printing business in North Mankato, Minnesota. In 1975, after working at nearly every job in Carlson and helping to double its size, Taylor purchased the company, and Taylor Corporation was born.

For more than 45 years, Taylor Corporation has continued to innovate and expand into a company of extraordinary depth and diversity, evolving into an industry-leading provider of print, communications, marketing technology and interactive solutions.

Guiding Principles

What hasn’t changed are the principles that have guided both Taylor and the company along the way.

- The belief there is always a better way.

- The pursuit of excellence in every detail.

- A focus on what others can’t or won’t do.

Leadership Team

Taylor’s leadership is comprised of industry experts passionate about innovation, enhancing client business operations, and building teams of dedicated and motivated professionals.

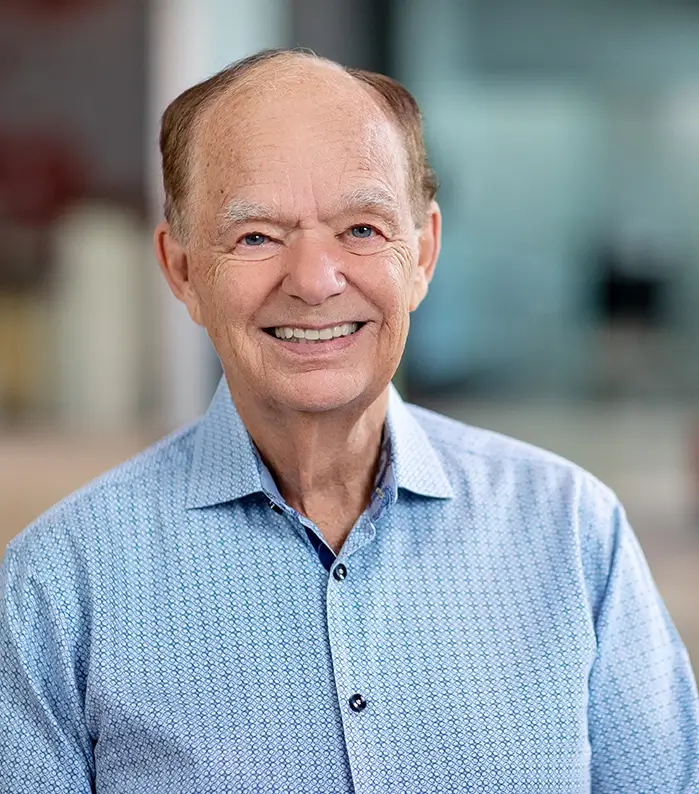

Glen Taylor

Chairman & Founder

Glen started his career with Carlson Wedding Service while attending college. He later purchased the business in 1975, assembled a passionate leadership team and dramatically expanded the firm’s capabilities through acquisitions and startups, bringing its spirit of ingenuity across markets and international borders.

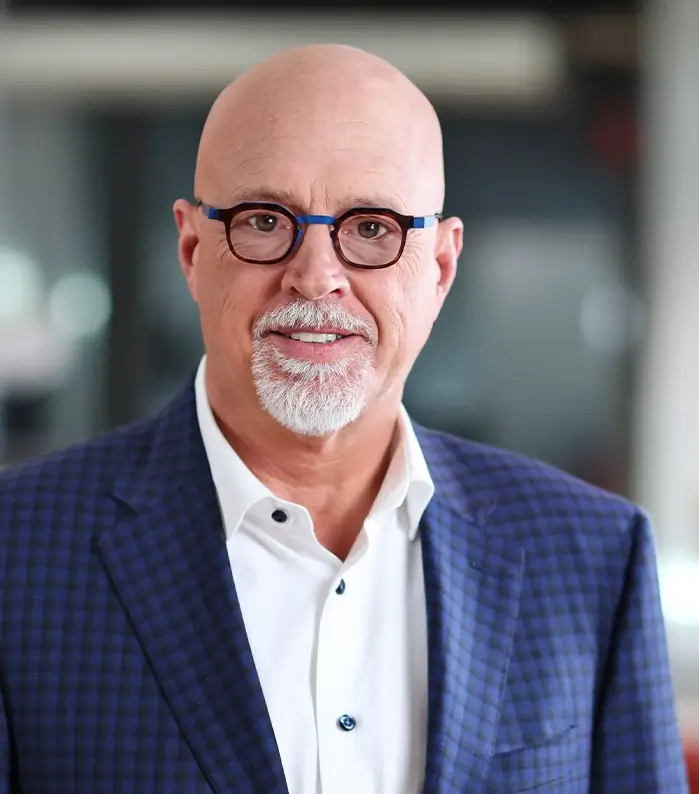

Charlie Whitaker

Chief Executive Officer

After 30 years in the paper and printing industry, Whitaker joined Taylor as executive vice president and has been with Taylor for 11 years. After leading several of the company’s businesses after their acquisition, he was named CEO in 2020 and is committed to unifying our diverse family of businesses into one team to achieve success and growth.

Scott McDonald

Chief Financial Officer

Scott is in his first year at Taylor and serves as the Chief Financial Officer. He has extensive international experience in corporate, operating, and governance leadership roles across a wide range of finance functional areas. This includes strategy formulation and execution, business turnarounds, mergers and acquisitions, and enterprise transformation.

Bob Makela

Corporate Treasurer

Bob has worked for Taylor for 31 years and has held a variety of positions including Controller, Tax Director, and currently as Corporate Treasurer. He is also the Chair of Taylor's 401(k) plan for all employees. With expertise in financial management, retirement plans, acquisitions, loan agreements, tax planning and risk management, he helps support numerous financial initiatives for the entire organization.

Carolyn Erickson

Chief Human Resources Officer

Carolyn has served as the Chief Human Resources Officer at Taylor for four years. She has extensive expertise in strategic and field HR, talent acquisition, learning and performance, total rewards, payroll, benefits, employee support, and internal communications.

Tru Pettigrew

Chief Diversity Officer

Tru is the Chief Diversity and Inclusion Officer for both the NBA’s Minnesota Timberwolves and the WNBA’s Minnesota Lynx. He also serves as the Chief Diversity Officer for Taylor, overseeing all diversity, equity and inclusion efforts, including the direction for Taylor’s Diversity, Equity and Inclusion programming.

Tommy Merickel

Chief Sales Officer

Tommy has worked for Taylor for 35 years and has held a variety of positions, providing decades of expertise and driving significant growth in each. He currently serves as the Chief Sales Officer for Taylor, focusing on building business relationships as a Taylor ambassador, driving sales development and strategizing organic growth plans.

Glenn Bottomly

Chief Marketing Officer

Glenn has worked for Taylor for 11 years and serves as the company’s Chief Marketing Officer, leading the organization’s overall marketing strategy. He has expertise in market research and communications, digital and product marketing, creative, brand, customer experience and relationship management, sales enablement, innovation, public relations, and social media.

Charlie Hipp

Chief Information Officer

As Taylor’s Chief Information Officer, Charlie leads information technology teams and offshore technology labor operations for the company. He has worked for Taylor for 14 years, managing both internal and customer-facing systems that power the organization’s corporate shared service platforms.

Jay Parker

Chief Supply Chain Officer

Jay has been with Taylor for 30 years, serving in a variety of roles in multiple Taylor companies. As Taylor’s Chief Supply Chain Officer, he leads a team that manages raw materials purchases indirect expenses, capital and logistics expenditures, supplier relationships, and supply chain data analytics.

Susan Drenning

Enterprise Group President

Susan has worked for Taylor for 30 years, serving in a variety of businesses in multiple roles across the organization. Her areas of expertise include product innovation, digital and direct marketing, customer lifecycle management, brand development, and business transformation and optimization.

Dennis Duchene

Enterprise Group President

Dennis has worked for Taylor for three years, and leads an exciting portfolio of companies including our Document Management, Labeling Solutions and Office Products businesses. He brings with him a broad range of business experience leading business groups in a variety of industries.

Nate Mullikin

Enterprise Group President

Nate has been with Taylor for 18 years, and brings a variety of business experience and skills in many areas to the leadership team. These include customer service, sales leadership and architecture, lean manufacturing, business transformation, technology, acquisitions, employee engagement, and servant leadership.

Mike Robinson

Enterprise Group President

In the eight years he has worked for Taylor, Mike has enjoyed leading, motivating and investing in others to achieve positive growth for the company. His areas of expertise include business strategy, execution excellence, operations, customer experience, financial analysis and performance management.

Andrew Bittner

Business Unit President

Andrew has been with Taylor for 16 years and his areas of expertise include data strategy, data application development and data science. He has also focused on business process optimization, supply chain management, financial analysis and sales administration.

Jason Greenfield

Corporate Vice President

Jason has been with Taylor for two years and currently serves as Corporate Vice President of Properties and Engineering, leading the organization’s overall real estate, facilities and engineering strategies. Jason brings extensive expertise leading custom machine automation, lean process engineering, software development, real estate transactions and international construction. He supports all business units in achieving their strategic objectives through new technologies, continuous improvement, project management and operation analytics.

Chris Austin

Corporate Vice President

Chris has worked for Taylor for 11 years and serves as the company's Corporate Vice President of Tax and Assistant Treasurer. He has extensive expertise as a Certified Public Accountant and expertly leads our company's global tax strategy, overseeing tax planning, managing risk and opportunities within tax regulations, ensuring adherence to international tax laws, all while upholding our company's values and contributing to its sustainable financial growth.

Turning printing into long-term partnerships

We Serve

7 of the Top 10

U.S. Manufacturing Companies

9 of the Top 10

Financial Institutions

The Top 3

U.S. Home Improvement Retailers

The Top 10

U.S. Retail banks

The Top 3

U.S. Credit Unions

The Top 3

U.S. Wireless Providers

A World of Capabilities

Brands are built on consistency. Taylor’s global reach ensures you get the unwavering service, support and execution you need.

This could be the start of a beautiful partnership.

We’ve been at this a long time. We’ve partnered with companies large and small to develop and implement print, marketing and technology solutions that increase businesses and brand recognition. We want to know what your goals are — and how we can help you reach them.